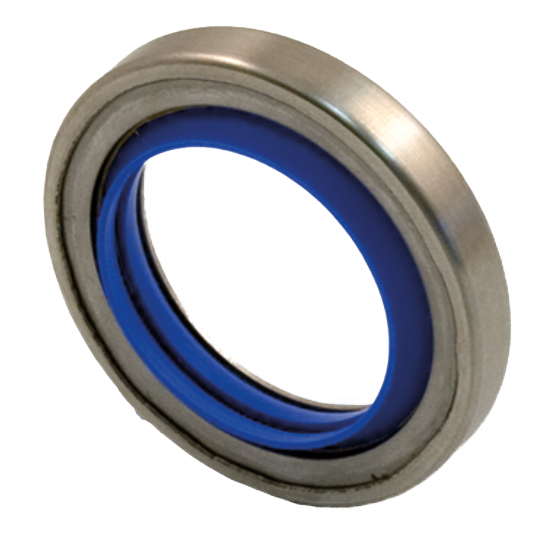

Lip seal systems

This sealing technology complements our product range with a sealing solution for low-speed applications with the risk of dry running or insufficient lubrication with liquid medium

Technical designs

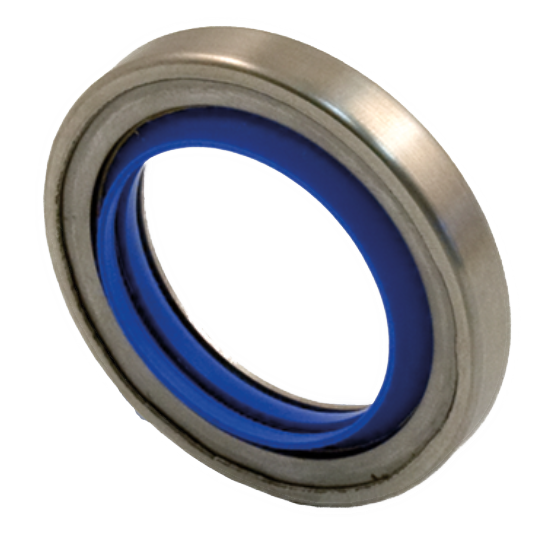

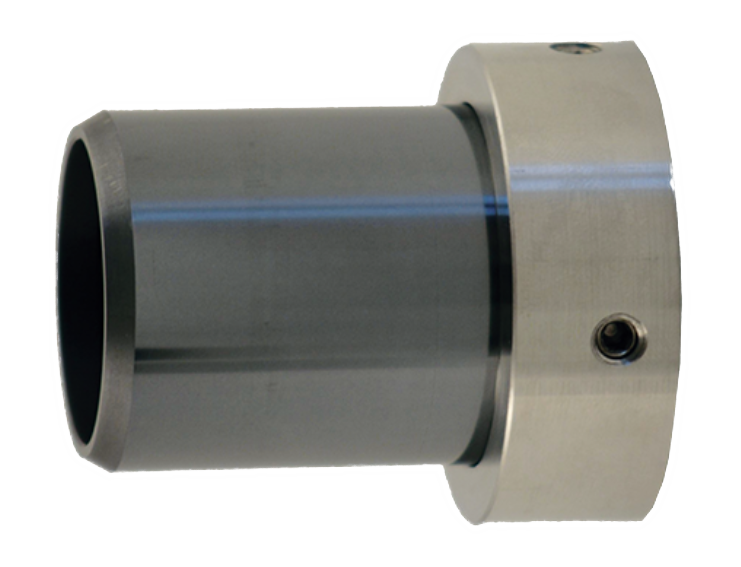

Our unique seal design combines the low-friction properties of PTFE with the exceptional hardness and thermal conductivity of silicon carbide. This ensures optimal performance and durability in demanding applications.

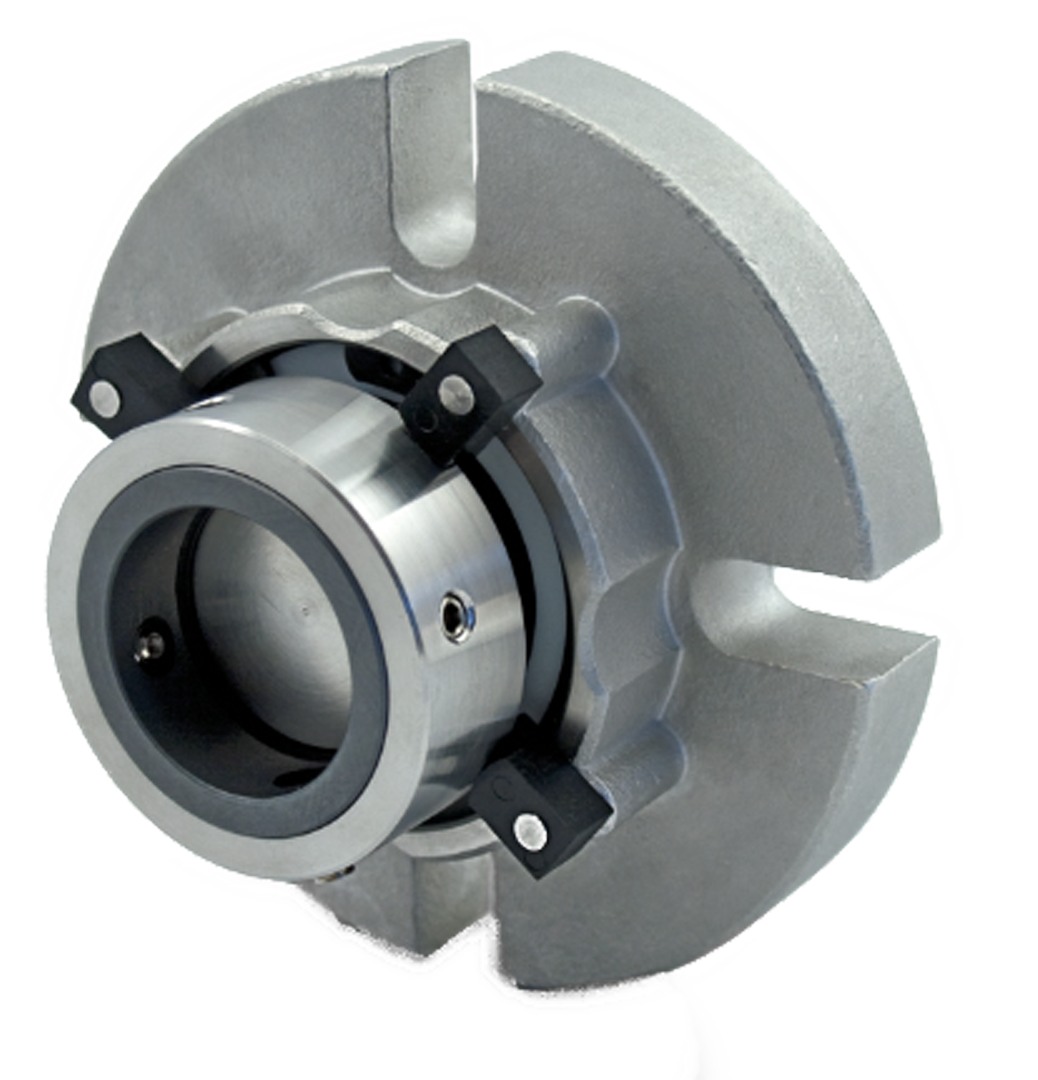

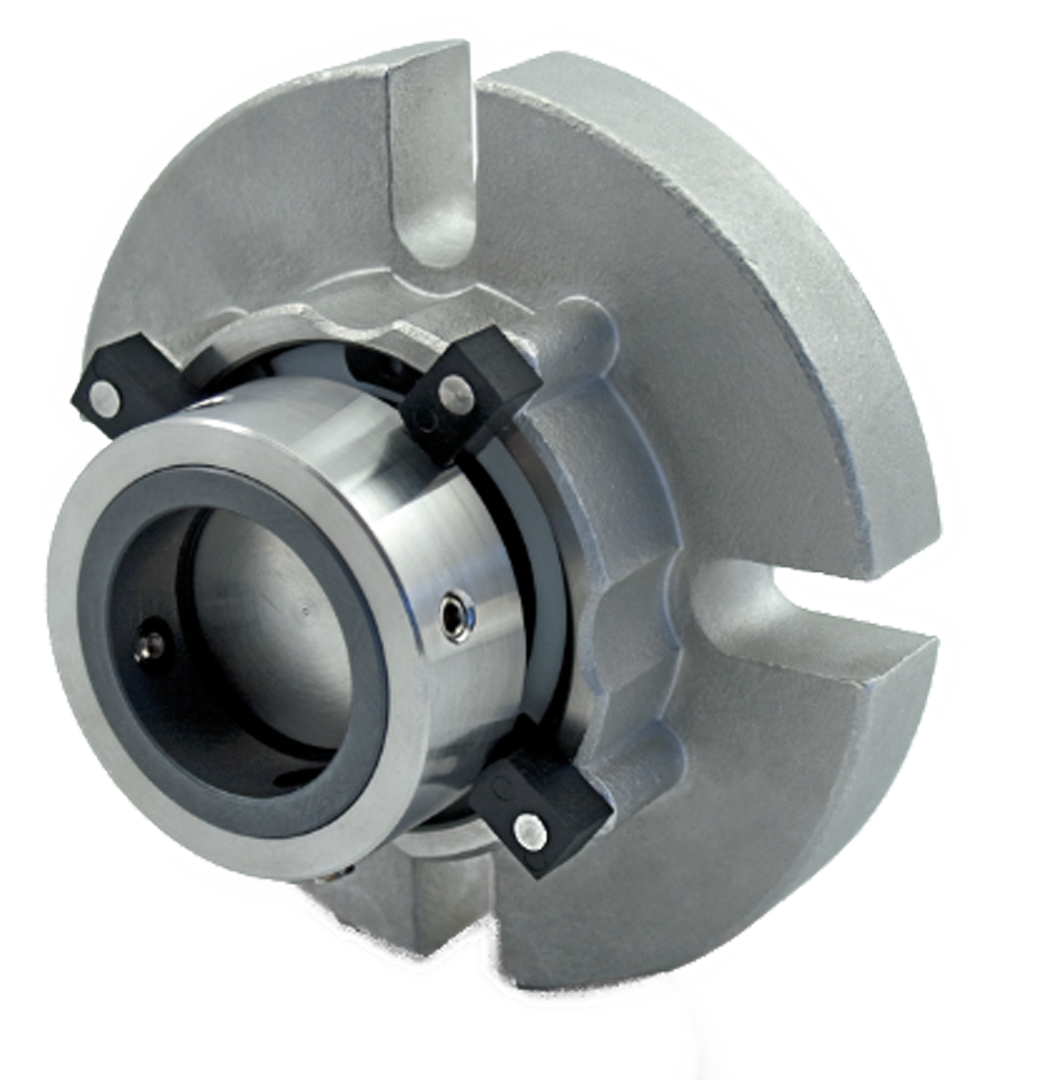

Complete systems

For mixing and stirring technology, as well as special pump applications, there are innovative ways to manufacture compact and cost-effective sealing units. We configure these together with the machine manufacturer as a customized system that is delivered exclusively.

Basis for success

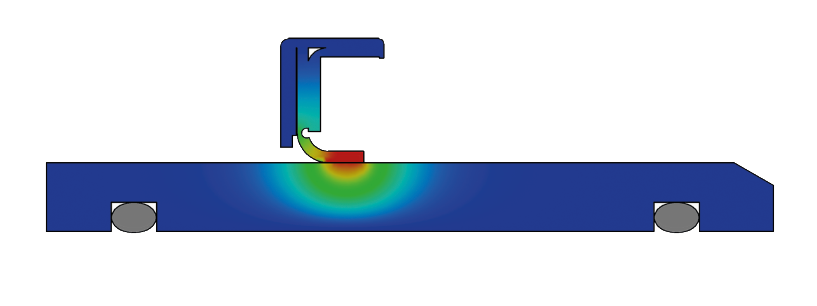

Technological concept

Technological concept

Design feature

■ Ready-to-install sealing system ■ Silicon carbide shaft sleeve ■ Simple design ■ Vacuum up to 20 bar ■ Dry-running properties ■ Tight fit ■ Corrosion and heat resistant ■ Gas barrier available

Technical designs

■ Standard version with pre-seal ■ Cartridge versions with integrated bearings ■ Versions to compensate for increased radial misalignment ■ Dry-running seals for high speeds with separate cooling by liquid media ■ Versions in accordance with TA-Luft (Clean Air Act) ■ Versions in accordance with ATEX ■ Metal-free versions ■ CIP and SIP capable

Complete systems

For mixing and stirring technology, as well as special pump applications, there are innovative ways to manufacture compact and cost-effective sealing units. We configure these together with the machine manufacturer as a customized system that is delivered exclusively.

Key areas of application Applications

Vertical pumps

Dry-suction pumps

Pumps with a risk of dry running

Mixers and agitators

Vacuum technologyPharmaceutical applications with

gas barrier■ Hygienic design

Basis for success Technological concept